Tuesday, April 16, 2024

Neumann PA2a 💫

Glad I helped my pal Daniel Kim to find and purchase this gem from the past: Neumann PA2a turntable and SEV1 Phono EQ.

It was - reportedly - the property of Herr Georg Neumann, himself 🤩

Sunday, April 14, 2024

Oldest records shop in the world 💫

The world's oldest record store: Spillers Records, est. 1894, at it's original location, Queen's Arcade, Cardiff, Wales.

Saturday, April 13, 2024

The Music is back 💫

I was forced to be stuck at home for some weeks without my beloved music in my Studietto, but… today, at last, I spent three hours with a dear friend listening to some still unplayed records I piled up.

What can I say?

The pleasure of good company, sharing music and chatting is priceless… and the Analogtechnik’s Ice Age cartridge is well-played, now and in full bloom in 13” The Peak arm… amazing!

The overall sound is truly cohesive and coherent - every part of the audio system is working in harmony, nothing disturb the life-like flowing of interwoven musical beauty.

Magical, indeed…

Thanks to my pal Silvio for enjoying with me… Music 💫🎼💫

Holiday Inn & The Who

Thanks to Michael Trei for the following:

“When I arrived for AXPONA, I noticed that my hotel was tucked in behind another abandoned hotel. Curious, I did a little research, and found that this shuttered Holiday Inn has an interesting history.

Opened in 1966, The Who stayed here in June 1967 when they played at a club called The Cellar in nearby Arlington Heights. This was about a month before they were banned for life from all Holiday Inns following Keith Moon's 21st birthday party in Flint Michigan.

The show at The Cellar was cut short to about 15 minutes, due to the band violating some kind of local noise ordinance, so the band smashed their equipment and retired to the hotel earlier than usual. Back at the hotel, Pete Townshend started working on the plot and lyrics for Tommy using stationery from the hotel, nearly two years before the album was completed. Townshend also said in his autobiography that it was here that he had his first spiritual awakening.

The Rolling Meadows Holiday Inn closed in 2018, and is slated for demolition later this year.”

Great insight, Michael 💫🙏💫

Tuesday, April 2, 2024

Monday, April 1, 2024

Audio Origami Harlequin 39” arm

Introducing the Harlequin, the world's first 39" (1 meter) tonearm.

It is widely accepted that the larger your record collection, the larger the tonearm you require to bring out the best in each recording. Audio Origami has recognised this need and developed an extra-long arm with the rigidity necessary for people with large decks.

Based on Audio Origami's foolproof PU7, the new 39" Harlequin arm delivers a super laid-back presentation with unparalleled dynamics.

The armtube is made from Robustium, a new alloy with a naturally occurring carbon lattice that is nine times harder than diamond. Spacex currently uses Robustium to support Elon's ego.

Due to the inherent flammability of Robustium upon contact with moisture, we strongly advise using the included AO-branded Kevlar-coated gloves and eye protectors when handling the Harlequin.

Available 1st April

To order please call: 0123 456 789

Have a nice April’s Fool day 🥂

Sunday, March 31, 2024

Tuesday, March 26, 2024

RIP for Koetsu

It's with a very heavy heart, I sadly have to report that Koetsu is no more!

Having had a conversation with Koetsu's longest standing Distributor in the UK, Absolute Sounds, the simplified story is, that the family don't want the business to continue outwith their hands, and don't want to risk tarnishing the brands reputation and legacy by selling to an outside entity, which is honorable and admirable, in this day in age, too many originally family owned businesses have drifted from what was originally intended, take Gucci as an example, now a massive corporation with no family members involved, and dare I say long lost their original direction.

So please savour and cherish your Koetsu's as they are now heirlooms from another era, on a brighter not Absolute Sounds have established an arrangement with a trusted Cartridge repairer/rebuilder who they can send cartridges to for quality work which will be returned with frequency response graphs after thorough testing.

RIP Koetsu

Thanks to Mark Charles Stewart for the above…

Saturday, March 23, 2024

Wednesday, March 20, 2024

Monday, March 18, 2024

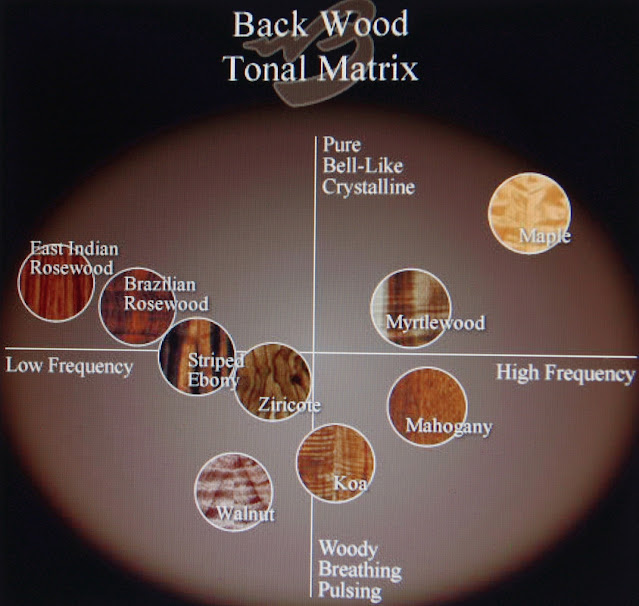

The Wood - best music friend 💫

This article http://tonewooddatasource.weebly.com/technical-data.html?fbclid=IwAR2djnLjoxEFCZLDQVBa4XmThHxabqHn9nY9ORSeDOBejh69bOoeqgCM29w_aem_AZgTSBl7DAgdRvCSrHQmaL3bPaTGXPcuVh0r5ia6wUjTibiWQ7sql9Fv0xZAzj2-nmk is amazing in clarity, completeness and enlightenment.

Tuesday, March 12, 2024

juHrop by Frieder Butzmann - a Klingon opera 💫

Frieder Butzmann (2LP Box) |

Diamanda Galás is a legend. Frieder Butzmann has been referred to as the "father of German experimental music", yet he is still unknown to the most. Now is the time. A unique amalgamated mixture of lysergic electronica, an aural whirlwind filled with surreal ramblings, tape collages, field recording, phone calls, roaring sounds, chirping cricket orchestras, squealing sound fragments of synthesizers galore. The opera “juHrop” was recorded with great effort at the Studio für Komische Musik Berlin and at the studio of Diamanda Galas in New York from 1996 to 2001. It is orchestral music produced with electronic devices and voices of Chinese singer Wu Jiang, David Moss, Diamanda Galas, Udo Scheuerpflug, Margarete Huber and the Moabiter Motettenchor. It was broadcasted in full length on “Deutschlandradio Kultur” in 2009. |

.jpg)

.jpg)